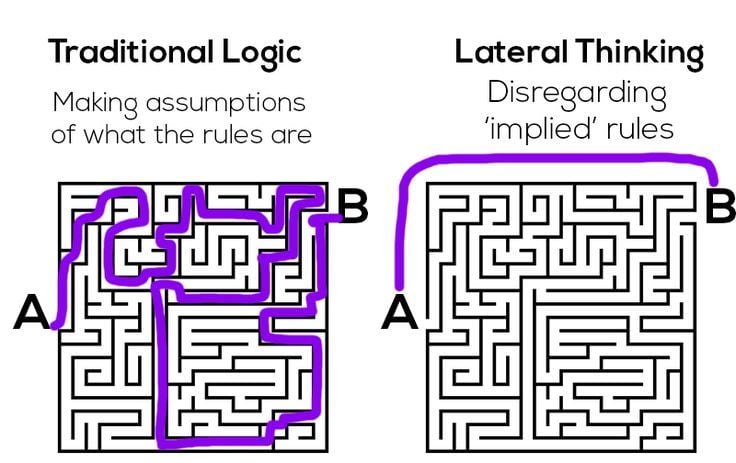

We constrain our self when we box ourselves in. When we do this, we fail to see solutions outside of the status quo. If you have boxed yourself in… simply get rid of the box. For me, Lean Six Sigma helps to remove the box. Think of watching a movie in high definition (HD), can you recall what an image looked like prior to HD television? Similarly, looking at the world through the lens of a Lean Six Sigma Black Belt or Master Black Belt provides us a high-resolution and clear image of a problem.

Lean Six Sigma is a skill that will not only improve our metacognitive capacity, but a skill that will improve our earning capacity as well. Some of the most successful businesses in the world use this as well. This one skill set will not only transform the way you think, but it will also make you extremely marketable to top organizations looking for change agents and problem solvers.

What is Lean Six Sigma?

Lean Six Sigma is a customer focused and data-driven problem-solving method with the goal of improving quality, cost, and speed. It uses the DMAIC problem-solving methodology, where you:

Define the problem Measure the baseline Analyze the process and find the root-cause of the problem Improve the process and implement best solutions Control the process and sustain the gains

Lean Six Sigma not only allows us the ability to solve a problem, but it educates us on what a problem is. A problem is essentially a gap between how we view reality and what reality actually is. It is a framework for understanding our paradigm and our mental models within the world we live in. Now that you have a basic understanding of what it is and why you should learn it, let’s take a look at my top 4 tools and techniques within Lean Six Sigma.

Learning to See by Mapping Out Your Process

The first thing we must understand is that we must see the process and stop operating blind. You can learn to see by mapping out your process. By mapping out the process from point to point, we find it easier to uncover waste. Furthermore, by mapping out a process we start to see an accurate picture with a higher resolution.

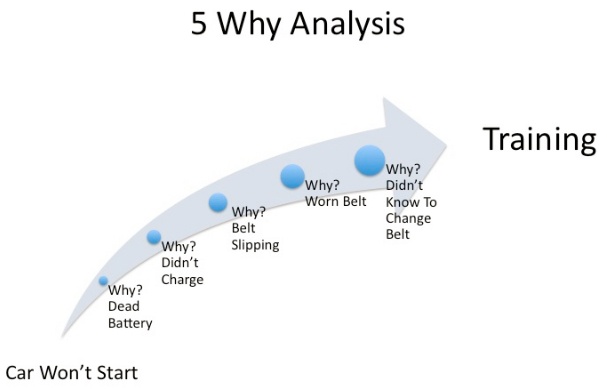

5-Why

Are you ready for a technique you mastered at the age of five, yet you forgot how to use? Simply (and annoyingly!) ask “Why?” over and over again. The 5-Why technique is an extremely powerful and valuable tool allowing us the ability to peel away the layers of symptoms to get to the core of the problem.

Remove Waste

Waste in a process is whatever the customer defines it as. Once the customer defines his or her value, we must then prioritize our value-added activities. First, immediately eliminate all non-value added activities that do not serve a purpose. Second, look at reducing the amount of non-value added required activities. These are things that add no value, yet are required by law or regulatory guidance. One simple way to do this is to ask, “Why are we doing this?” and “Do we still need to do this?” Third, optimize those value-added activities, which are the things that are already working.

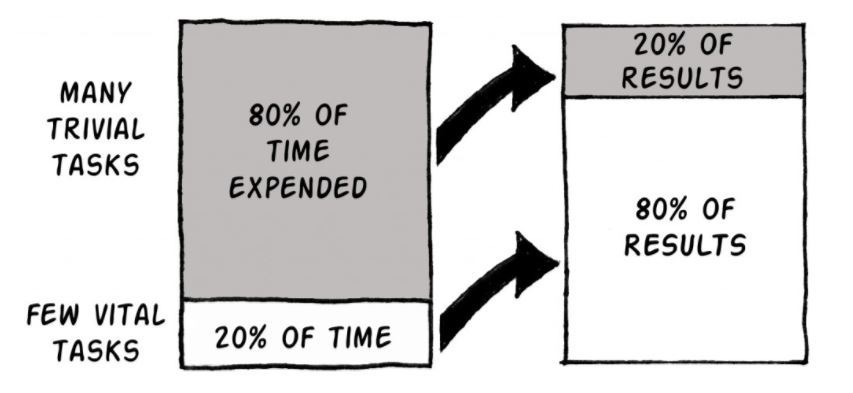

Pareto Principle

Using the 80/20 rule (based on the Pareto Principle), we can identify the 20% of actions causing 80% of the problem. Or looking at it from a different angle, we can identify the 20% of actions bringing in 80% of the profit. Named after Vilfredo Pareto, the Pareto Principle uses a Pareto chart, which is simply a visual aid for identifying “pain” or “opportunity” areas.

Seeing Beyond the Problem

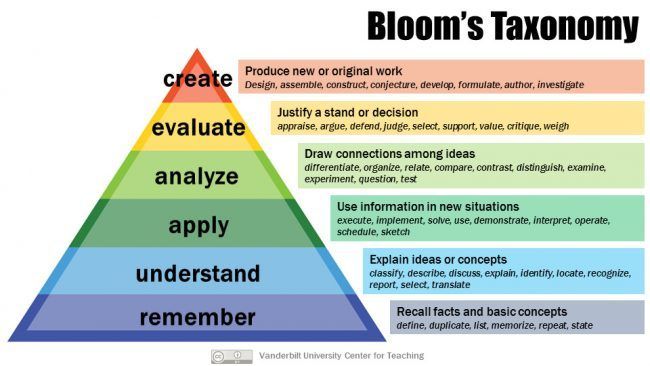

Lastly, I recommend Blooms Taxonomy of Learning to determine if you are actually seeing a problem in HD. This is a good tool to use to make sure you are using your metacognitive skills and not simply regurgitating information.

Here are some questions to ask yourself:

Can you define or describe the problem? Do you comprehend the meaning of the problem? Can you apply the information you have? Are you able to break down objects into similar parts and analyze those parts? Can you rearrange or assemble ideas into a new whole? Are you able to evaluate and judge information based on evidence? Can you solve the problem, create something new, and describe your thought process to someone with no understanding of the problem?

I hope all these techniques I introduce to you can help you start to see a problem in HD and get rid of the box that stops you from coming up creative solutions.